We are a biopharmaceutical company focused on the development and commercialization of products that address unmet patient needs, with current focus directed towards the treatment of pulmonary arterial hypertension (PAH).

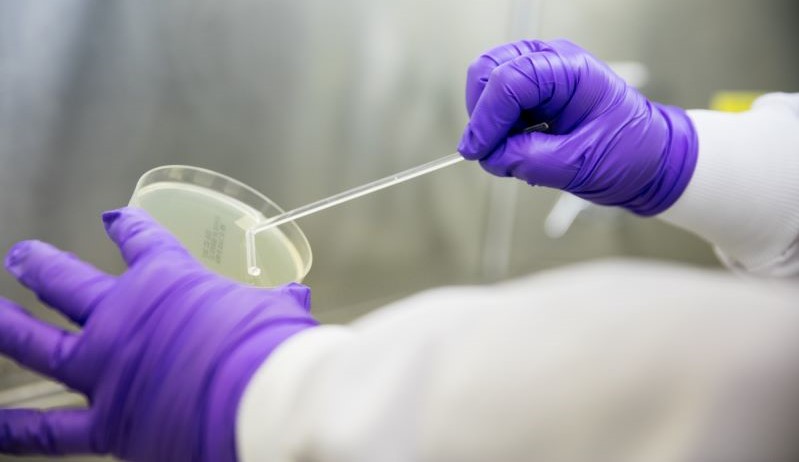

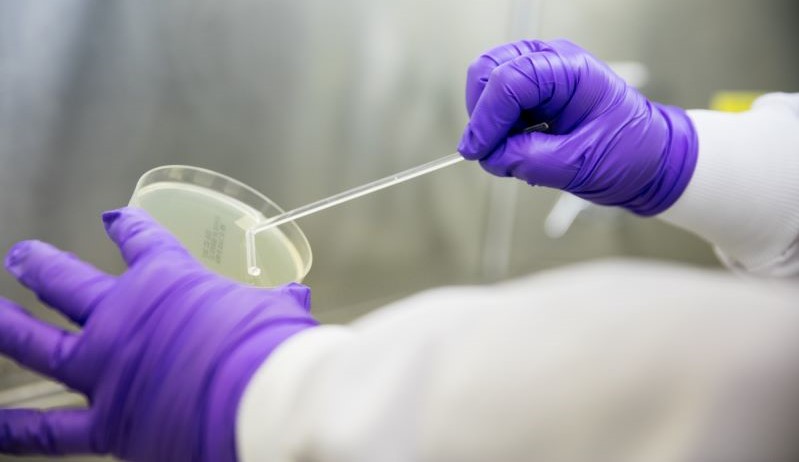

Liquidia conducts research, development and manufacturing of novel products by applying its proprietary PRINT technology, a particle engineering platform, to enable precise production of uniform drug particles engineered to improve the safety, efficacy and performance of a wide range of therapies.